TPS Study Mission to Japan

Facilitated by Toyota Engineering Corporation

Registration Deadline: 31st March 2024

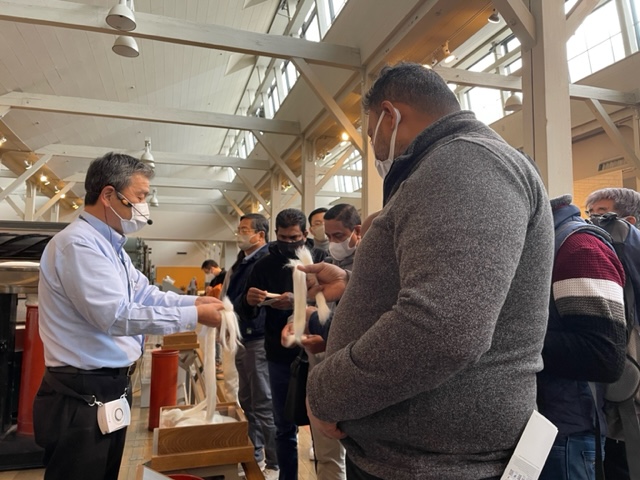

We, the Center for Lean Excellence, are proud to facilitate the TPS study mission to Japan in collaboration with Toyota Engineering Corporation. This mission is solely focused on providing the optimal learning experience in TPS for manufacturing excellence practitioners worldwide. The tour encompasses workshops, guided factory tours, face-to-face interviews with leaders who have successfully implemented TPS, networking sessions, and immersive Japanese cultural activities.

The learning in this program is aligned with TPS Grade IV, TMS Grade IV, and TPS Grade III programs, allowing participants to complement their classroom sessions with practical engagement. Toyota Engineering Corporation enables participants to engage in interactive gemba activities and Q&A sessions with leaders, providing a comprehensive understanding of TPS implementation in a factory setting.

Next Study Mission

BEST FOR

for CEOs, COOs, Operational Leaders and Senior Managers

TIMELINE

Arrival: 19th May 2024 | Departure: 25th May 2024

WORKSHOPS

Two full-day workshops

FACTORY TOURS

Four Guided Factory Tours

CERTIFICATE

Printed & Digital Certificates from TMS TPS Certificate Institute- Japan

Visit Itinerary

- Arrive in Japan & Travel to the Hotel at Nagoya | Check in Time – 3.00 pm

- 5.30 pm – 9.30 pm : Orientation to Japanese Culture. Japanese Traditional Tea Ceremony & Dinner

- 9.00 am – 5.00 pm : Toyota Cost Management | Full-Day Workshop by Mr. Toshio Horikiri

- 6.30 pm Onwards: Japanese Dinner & Networking

- 9.00 am – 5.00 pm : Hands-on Experience in Obeya Activity | Full-Day Workshop by Mr. Matsudaira

- 6.30 pm Onwards: Japanese Dinner & Networking

- 8.00 am – 12.00 pm : Factory Visit 1 – AVEX (Brake, Transmission & Engine Parts Supplier to Toyota)

- 1.30 pm – 5.30 pm : Factory Visit 2 – MIFUNE (Press Automation Solution Provider to Toyota)

- 6.30 Onwards : Japanese Dinner & Networking

- 8.00 am – 12.00 pm : Factory Visit 3 – Somic Ishikawa Inc (Suspension Ball Joint Supplier)

- 1.30 pm – 5.30 pm : Visit 4 – Toyota Commemorative Museum of Industry and Technology

- 6.00 pm: Certificate Ceremony

- 9.00 am Onwards: Hansei Reflection Break (Participants to use the day for reflection and site seeing in Japan)

- Departure to Home Country

Visit Highlights

Toyota Cost Management Workshop

TCMS (Toyota Cost Management System) is Toyota’s way of managing costs and its financial culture. Developed by experienced Toyota experts at TEC, it covers Cost Design, Target Costing, Cost Planning, and Cost Control at Toyota Motor Corporation.

Participants will learn TCMS concepts from experts and practice them through case studies. This helps them understand TCMS and apply it in their work.

Oobeya Experience Workshop

Oobeya is a visual project management space utilized in Toyota, where cross-functional teams convene to simultaneously undertake activities related to new product development, project management, or Hoshin management.

The team learns the details of the Oobeya concept, collaborates with senseis to engage and grasp real Oobeya practices, and gains the knowledge needed to implement Oobeya in their own workplaces.

Factory Tour I - Mifune Inc.

A benchmark-level Toyota supplier manufacturing facility with the outstanding application of TPS in many areas such as SMED, Kanbans, Supermarkets, Hijunka, Visual Management & Process Standardization. It’s remarkable to see how the plant process manages nearly 1500 different products using practical TPS methodologies.

The Top leadership of the facility will engage with the participants at Gemba to explain the processes and will have Q&A sessions on TPS and TMS (Toyota Management System) implementation from the Lean Leadership point of view.

Factory Tour II - Avex Inc.

An Impressive fully automated manufacturing facility with digital lean concepts in practice. It is a fantastic experience to walk through the process and understand the details and TPS practices at Gemba.

Different levels of Kaizen activities, digitalization and automation, and observing standardized work practices in an automated environment are key highlights.

Factory Tour III - Somic Inc.

Being a top tire 1 supplier to Toyota, Somic is a great place to visit and observe TPS adaptability and practices in the Toyota Supply chain. A detailed Gemba walk on the shopfloor will make you understand the overall TPS and TMS practices in place and how the organization continuously improved with TPS throughout the time to become a benchmark supplier to Toyota.

Factory Tour IV - Toyota Museam

A great journey through time to understand the history and evolution of Toyota. Toyota Engineering Corporation Sensei will make the visit more than an observation experience with detailed explanations of events and artefacts.

- Investment : USD 4350

- The above cost does NOT include airfare and visa-related expenses

- All related costs, including workshops, factory tours, airport pickup, airport drop-off, hotel accommodation, meals, and factory transportation charges, are included in the above price.

Contact us for more details:

Email : hello@centerforlean.com

Crafting Life Long Learning Experiences

Toyota Engineering Corporation

The Leading TPS Kaizen Consulting Firm in the World

Toyota Engineering Corporation is established in 2002. Their team of TPS professionals has over 35 years of experience implementing Total-TPS to enhance quality, increase productivity, and foster talent development at Toyota Motor Corporation and its affiliated partners. see more..

Meet Your Senseis

Toshio Horikiri

Chairman of Toyota Engineering Corporation

2017 – Present: Chairman

Toyota Engineering Corporation & TMS TPS Certification Institute Japan

2008 – Present: CEO Toyota Management Institute, Nagoya, Japan

Provide training on Toyota way Management System (TMS) to help company in effective and innovative management.

2008 – Present: Chief Director TMS & TPS Certificate Institution

Promote operation excellence into manufacturing and non-manufacturing places

2000 – 2002: Chief Engineer

Overseas Production Support, Motomachi Plant

Delivered TPS instruction/training and implementation for overseas Toyota plants in Southeast Asia,

Australia and India

1994 – 2000: Chief Engineer

China Project Division and Overseas Production Planning Division

Led production planning and promotion of new plant in China to ensure smooth and effectivelaunching with in the target time flame

1990 – 1993: Chief Engineer

Overseas Production Planning Division

Led production planning and effective vehicle launching

1987 – 1990: General Manager

Engineering and Manufacturing Department, Kuozui Motors ltd., Taiwan

1979 – 1987: Assistant Manager / Manager

Overseas Manufacturing & Engineering Division

1966 -1979: Assistant Manager

Body Engineering Department of Manufacturing Engineering division

Mr. Yasuhito Matsudaira

Senior Consultant at TMS & TPS Certificate Institute of Toyota Engineering Corp.

Worked in Toyota Motor Corp since 1979

After joining Toyota Motor Corp in 1979, Mr Matsudaira worked in the production technology and manufacturing division, starting as a technical expert in mechanical parts welding and integrated manufacturing processes in Japan.

Then he held positions as assistant director/ general manager in production preparation and technology development for resin parts, chassis parts, electronic parts, and final assembly lines.

He also served as a project leader in launching new vehicle plants in the United States and Canada. More recently, he worked as a representative vice president for Primearth EV Energy Co., a joint venture between Toyota Motor Corp and Panasonic that produces secondary batteries for vehicles.

In 2017, Mr Matsudaira became a senior consultant at Toyota Engineering Corp and Toyota Management Institute. Now he is using his expertise in TPS and TMS to serve many industries beyond the automotive sector.

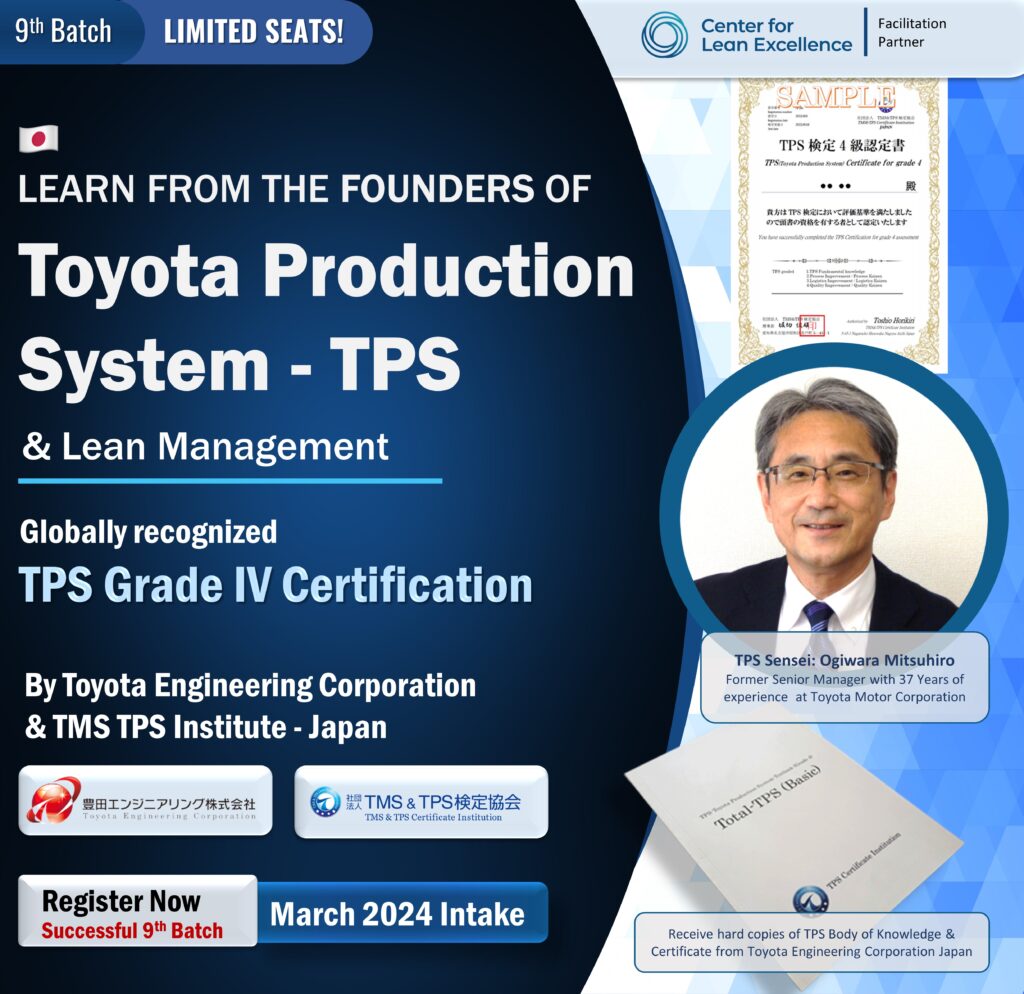

Learn TPS More

Proudly Organized by

Innovation Center for Enterprise Excellence Solutions (CLE) is a process innovation solutions provider specializes on Lean (Toyota Production System), Six Sigma and Total Productive Maintenance (TPM) concepts. Our vision is to enable potential by pioneering transformation for the good of individuals and enterprises. We deliver knowledge and solutions with our expert team that collectively possess 130+ years of hands on experience on enterprise transformation. To bring first hand lean knowledge, CLE has partnered with Toyota Engineering Corporation in Japan.