What is SPARq

Today, more organizations are looking for both digital and mechanical automation opportunities to deliver goods and services with minimal human intervention. Investing in an automation system is a critical decision with the high cost, time and resources required. Correct understanding and simplification of the current business process are crucial for an efficient, accurate, and sustainable automation system implementation.

SPARq is all about simplifying current processes and creating a “waste-free”, automation-enabled, lean future state that lays the foundation for smooth implementation of desired automation methodology.

What SPARq Offers You

- A comprehensive current state analysis of the client’s processes using the most suitable mapping technique for respective business categories. (CLE Lean Transformation Consultants possess 150+ years of collective experience in Airlines, Textile, Porcelain, Agriculture, Food and Tobacco industries)

- Quantification of Wastes, Manual activities, and Semi-Automated activities in the current state and provide practical countermeasures to Eliminate, Combine, Rearrange & Simplify process steps to achieve significant improvement in the process.

- An automation-enabled, waste-free, lean future state map is defined in collaboration with client company and automation service provider.

- A scientific change management program to guide, coach, and train client company employees to embrace and internalize the new system.

Why SPARq?

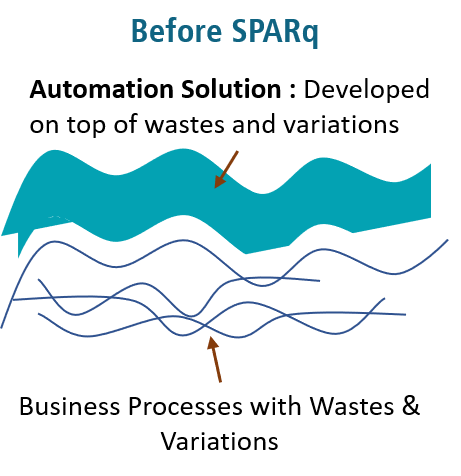

Businesses can automate mundane rules-based business processes, enabling business users to devote more time to serving customers or other higher-value work. ERP system development, Robotic Process Automation, and Industry 4.0 applications are some of the digital automation interventions many businesses are considering. According to Accenture, about 70% of automation efforts are failed due to various reasons. Two of the most common reasons are shown below.

- Process Automation without eliminating the wastes and variations in the current process

- Developing automation systems with less focus on business process future state

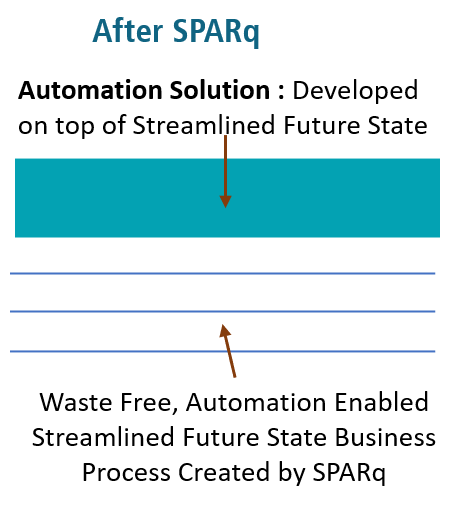

SPARq scientifically identifies wastes and variations in the current process and systematically develops the waste-free simplified future-state process that acts as the foundation for automation implementation.

A reactive Automation Solution. Wastes & variations in the business processes are automated. Expected business benefits and ROI of automation may not be achieved.

A proactive Automation Solution. The automation solution is implemented on a streamlined future state that creates a significant business impact. This enables process & people transformation while creating a unique competitive advantage

SPARq Approach

- Define Current State and Identify Wastes in the System

- Identify waste, excess touchpoints, manual activities, semi-automated activities, automated activities, and stagnation of material in the current material & information flow.

- Establish the Future State

- Develop a lean, streamlined, automation-enabled future state with minimal human intervention by eliminating, combining, reducing, and simplifying the current material flow to develop the automation system.

- Facilitate Change Management

-

Facilitate change management for people and material flow transformation for achieving the future state

-

SPARq Business Impact

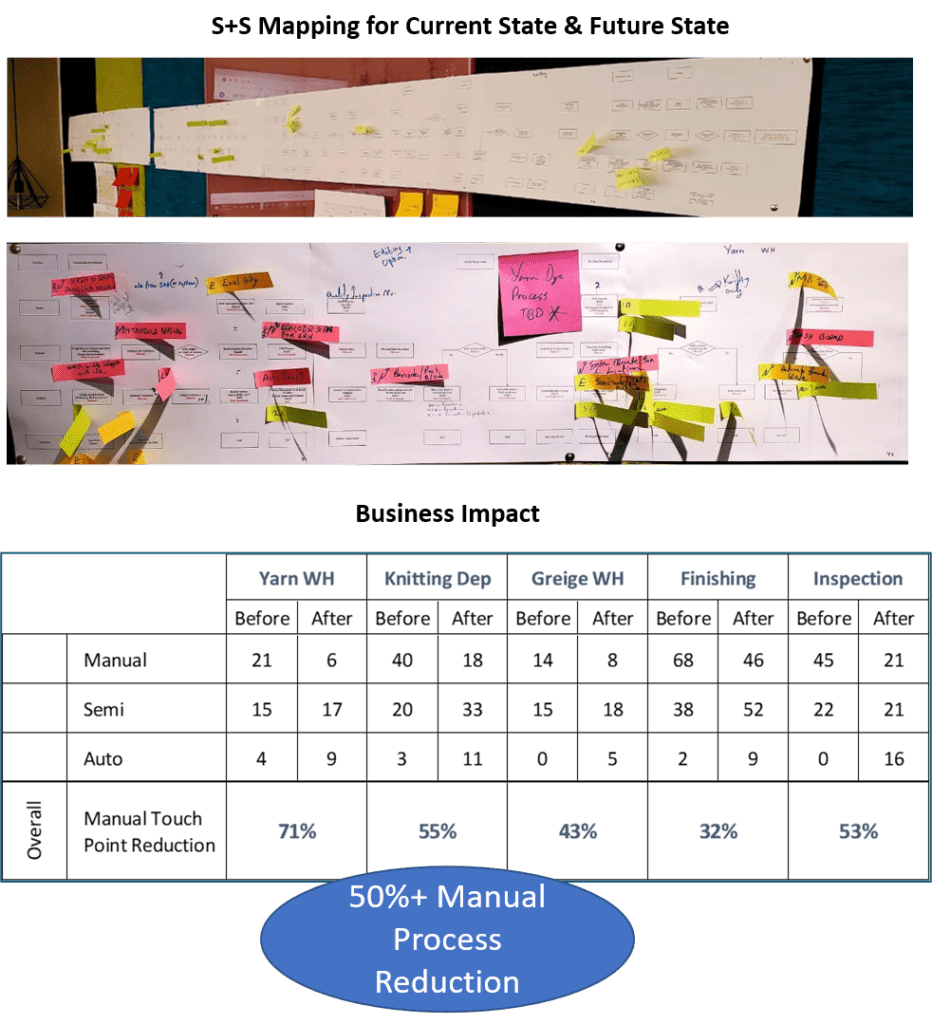

CLE worked in partnerships with digital automation solution providers to implement ERP systems and RPA (Robotic Process Automation) for varies organizations. In the initial phase of the engagement, the solution provider companies face challenges in analyzing the client process and quantifying the process improvement. CLE team provided SPARq with our own “S+S” current state mapping tool and manual process quantification techniques to develop an attractive business solution for the client.

Benefits to You as a Solution Provider

- Ability to outsource the business and process analysis part to CLE lean process coaches. They have more than ten decades of collective experience in business process analysis and improvements. You can leverage their expertise in understanding the exact requirement with a significantly short period of time

- Work with CLE team to streamline the business process and the system development process. In a typical process, there is a 50% or more opportunity in waste elimination and simplification.

- Develop a future state for the identified business process with best practices and embedding the lean true north vision. And build the automation on top of the future state. With this approach, the automated system will always be ahead of the competition and potential manual process improvements. (In some cases the manual processes are later improved to override the automated system, which tarnishes the credibility and the reliability of the automated system)

Benefits to You as a Client Company

- Considerable reduction in the project completion lead-time as CLE team is capable of identifying the critical process elements with various tools like Swimlane, SIPOC, Value Stream Mapping, Process Mapping, and Constraint Analysis.

- Opportunity to identify internal process improvement opportunities that could create a significant impact on the bottom line (Example: Capacity improvement opportunities, Quality, and Process stability opportunities, etc.)

- A new system is a change and the change should be managed scientifically. CLE team provides scientific change management support for the employees of your company and successfully guides them through the change cycle.