Toyota Management System

TMS (Grade IV) Certificate Program

By TMS TPS Certificate Institute & Toyota Engineering Corporation – Japan

Learn from the founders of Toyota Management System

Toyota’s automobile production method, known as the Toyota Production System (TPS), is renowned worldwide for its efficiency in improving quality, productivity, and delivery speed. While applying TPS to production and back-office functions, they developed Toyota Management System (TMS) to significantly improve productivity and reduce indirect costs in white-collar workplaces.

TMS is practiced by Toyota’s top management team, managers in production and indirect functions such as design, production preparation, and sales. This program will equip the participants with the TMS knowledge and skills to achieve improved results and transform your company into a stronger and better one.

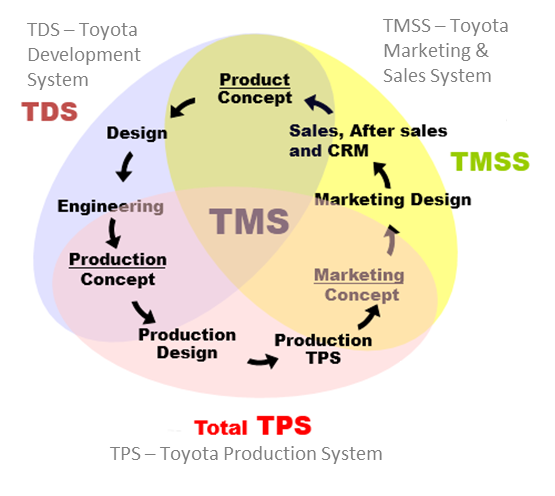

The Toyota Management System (TMS) is a comprehensive approach to a management methodology that can be applied in any industry or workplace. TMS is the underlying management system of Toyota Production System (TPS), Toyota Development System (TDS) & Toyota Marketing & Sales System (TMSS) . In this program, you will learn how to “Yarigai,” or turn ideas into practice and achieve workplace satisfaction.

TMS boosts productivity and reduces indirect costs through the implementation of Visual Management Tools and a method for total management, which facilitates continuous improvement (Kaizen) in the workplace and creates a supportive environment for people.

BEST FOR

C Suite, Director, Senior Managers, and Managers in Service & Manufacturing

DELIVERY

Online (ZOOM) | 20 Hours | 5 Saturdays

MATERIAL

Toyota Management System Text book

MODE

Instructor-led training (Executive TMS Sensei)

CERTIFICATE

Printed & Digital Certificates from TMS TPS Certificate Institute- Japan

- Introduction: 20th Oct 2024

- Session 01: 27th Oct 2024

- Session 02: 3rd Nov 2024

- Session 03: 10th Nov 2024

- Session 04: 17th Nov 2024

- Examination : 1st Dec 2024

Download Program Brochure

“Participating in this program helped me to get a deeper understanding of the Total Toyota Production System. Revitalization of the workplace and respect for people are two key takeaways for me. I started involving the people in my workplace in daily problem solving and was amazed at the number of kaizens that can be done on the shop floor. It was an honor to learn from Masters and the Toyota Engineering Corporation.”

Brial. J.L Pederson

Lean Specialist

Priess A/S Denmark

Key Learning Outcomes

- Visualization of action: Policy development, daily management, and visualization of tasks

- Creation of values: Customer focus and commitment to results

- Emphasis on quality of work: Statistical thinking and own process completion

- Creation of a better workplace: Communication and leadership

- Emphasis on Kaizen mindset: Identifying waste, organizing groups, and problem-solving skills

- Creation of profits: Systems for improving productivity and generating profits

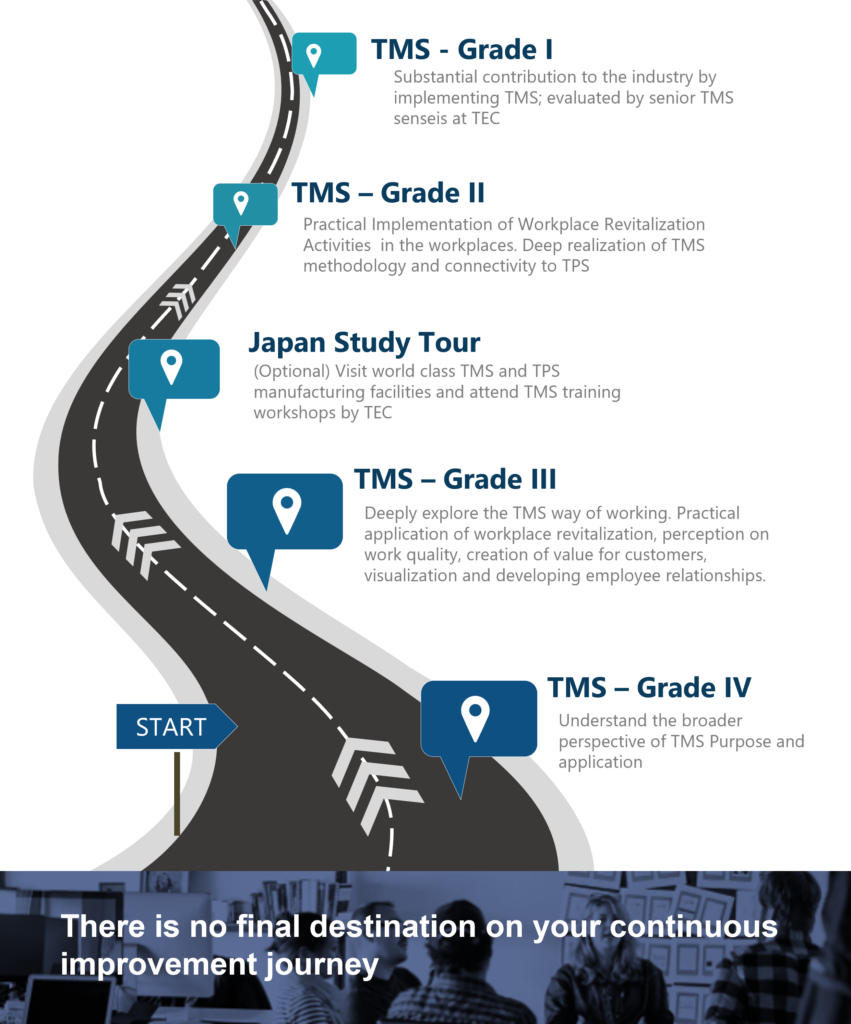

TMS Certification Journey

Toyota Management System Grade IV Program Content

- Day 01 (Conducted by the CLE Team)

- Introduction and Warm up Session

- Getting to know Lean Management

- Value, value-adding, and waste

- Setting up a lean manufacturing process in a new facility

- Value Stream Mapping for business

- Important points to know when implementing lean management

- Explanation of Lean Vocabulary

- Practical challenges of lean implementation and how to overcome

- Day 02

- What are Workplace Revitalization Actions?

- TMS Core is an Action that Makes the Workplace Better

- The “Way of Working” that will Become the Core

WRAs Ideal Person - Q&A

- Day 03

- Visualization of Action and the Theory of Visualization

- Visualization of Actions – Planning and Development

- Visualization of Actions – Daily Management

- Visualization of Actions – Visualization of Work

- Creating a Workplace (Team) – Communication

- Creating a Workplace (Team) – Leadership

- Creation of Value

- Q&A

- Day 04

- Continuous Improvement Mindset – Reflection

- Continuous Improvement Mindset – Spotting the Unnecessary

- Continuous Improvement Mindset – The 5S

- Continuous Improvement Mindset – The Ability to Solve Problems

- Work Quality – A Statistical Approach

- Work Quality – A Self

- Contained Process

- Creation of Profit – A Plan to Produce Profit

- Creation of Profit – Elevating Productivity

- Q&A

- Day 05

- WRA Introduction and Growth

- Putting WRAs Into Practice

- Regular Company Employees

- The Nucleus – Management Staff

Managers - Evaluation of WRAs

- Managerial Results

- Case Study

- Q&A

- Day 06 : Examination Day - Online

- TMS Grade IV Examination (80 MCQs | 90 Mins)

This Certification Program is Best Suited for

- Leaders in the Services (Banking, Hospitals, Marketing, Planning etc.) & Manufacturing

- Already qualified Lean Six Sigma Black-belts and Green-belts

- Entrepreneurs who want to develop a new dimension for their businesses

Transform Yourself Today!

- Investment : USD 795

* Postal / Courier charges will be separately billed for overseas participants

Contact us for more details:

Email : hello@centerforlean.com | Phone / Whatsapp : +6584806350 or +94777318299

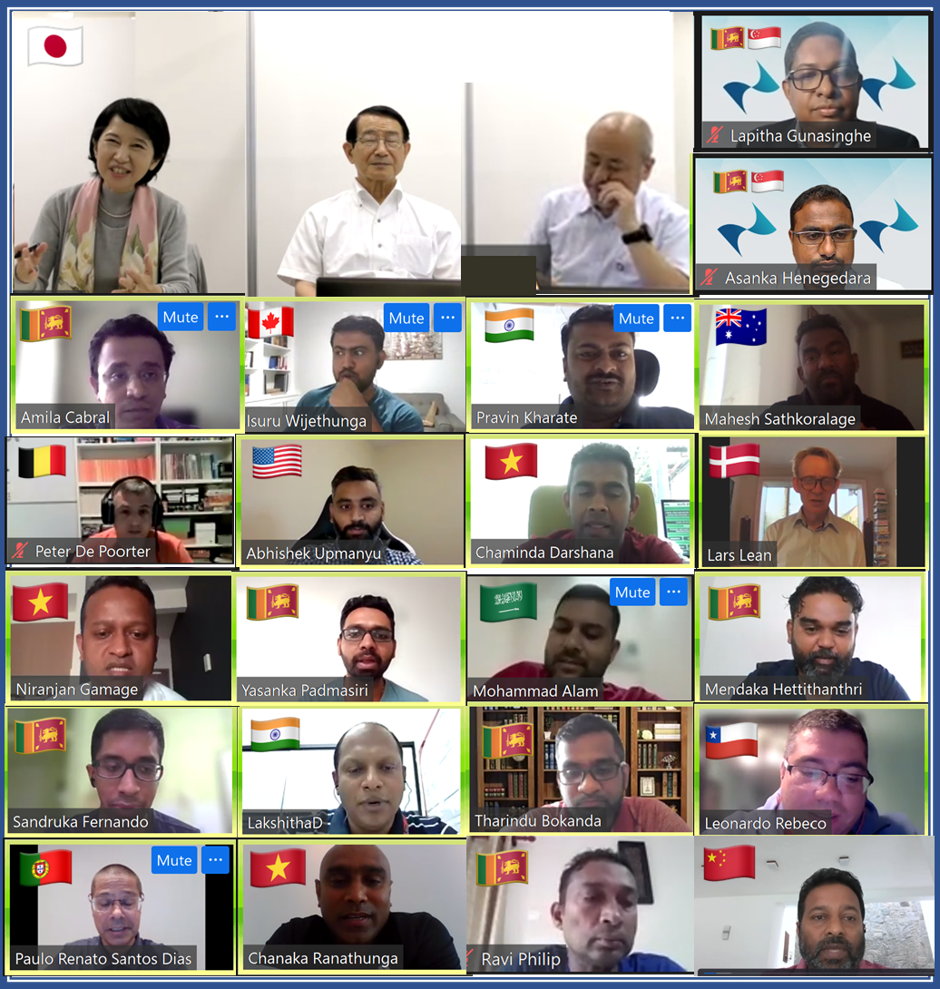

Join the Elite group of TPS Practitioners

Prestigious Certificate from Toyota Engineering Corporation

Learn from the WORLD'S BEST LEAN TMS Senseis

Meet Your Sensei

Mr. Yasuhito Matsudaira

Senior Consultant at TMS & TPS Certificate Institute of Toyota Engineering Corp.

Worked in Toyota Motor Corp since 1979

After joining Toyota Motor Corp in 1979, Mr Matsudaira worked in the production technology and manufacturing division, starting as a technical expert in mechanical parts welding and integrated manufacturing processes in Japan.

Then he held positions as assistant director/ general manager in production preparation and technology development for resin parts, chassis parts, electronic parts, and final assembly lines.

He also served as a project leader in launching new vehicle plants in the United States and Canada. More recently, he worked as a representative vice president for Primearth EV Energy Co., a joint venture between Toyota Motor Corp and Panasonic that produces secondary batteries for vehicles.

In 2017, Mr Matsudaira became a senior consultant at Toyota Engineering Corp and Toyota Management Institute. Now he is using his expertise in TPS and TMS to serve many industries beyond the automotive sector.

Join the Elite Group of 5000+ TMS & TPS Change Agents across the World !

Authentic Knowledge with Simpler Illustrations

- The TMS program is based on the most current knowledge: This means that the information in the textbook has been carefully researched and reviewed by experts to ensure that it is up-to-date and accurate.

- It is developed by experts: The textbook has been written by subject matter experts who have a deep understanding of the material and are well-versed in the latest research and developments in their field.

- It has been verified for accuracy: The content in the textbook has gone through a rigorous review process to ensure that the content is accurate and reliable. This may include fact-checkings, peer reviews, and other quality control measures.

Receive Your TMS Grade IV Hand Book to Your Door-step

Proudly Organized by

Center for Lean Excellence (CLE) is a process innovation solutions provider specializes on Lean &Toyota Production System concepts. Our vision is to enable potential by pioneering transformation for the good of individuals and enterprises. We deliver knowledge and solutions with our expert team that collectively possess 130+ years of hands on experience on enterprise transformation. To bring first hand lean knowledge, CLE has partnered with Toyota Engineering Corporation in Japan.