Lean New Product & Process Development

Virtual Masterclass

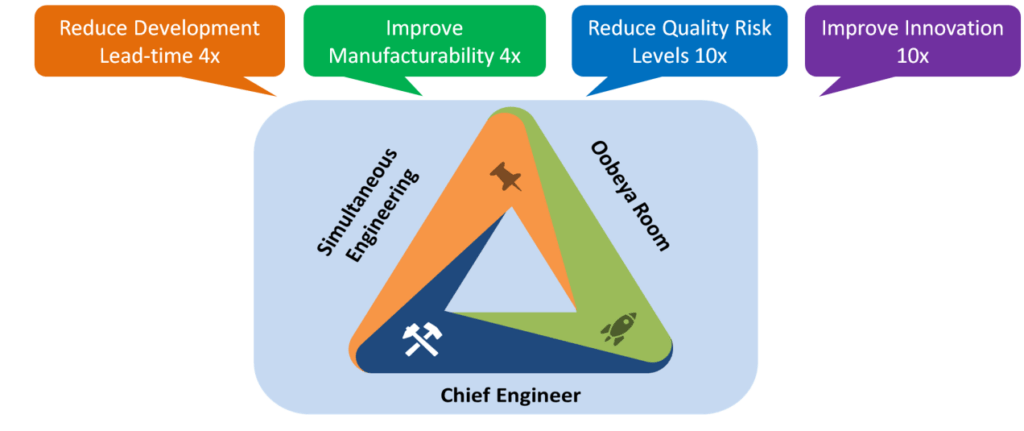

Program Outcomes

- Participants will learn the practical application of LNPPD concepts such as Simultaneous Engineering, Oobeya etc

- Significantly reduce development lead times and become competitive in the market

- Improve manufacturability of new products wit smooth bulk integration

- Improve innovation capability while reducing the product risk with the participation of all the teams

Program Content

- Day 01: Introduction to Lean New Product & Process Development

- Value & Wastes

- Usable Knowledge Measures

- 6 Wastes in Development

- Methods to identify wastes

- Day 02: Lean Startup Model

- Sources of Innovation

- Lean Startup Canvas

- ERRC Model

- Kano Analysis

- Methods to identify wastes

- Day 03: Simultaneous Engineering

- Front Loading

- FMEA

- Tradeoff Curves

- Target Costing

- Day 04: Sprint & Dev Kaizen

- Google Sprint

- Proto Typing

- Advanced Kaizen

- Sprint case study

- Day 05: Chief Engineer & Oobeya

- Visual Management

- NPD Project management

- Roles of Chief Engineer

- Value Stream Organization

- Day 06: Quick Changeover & Factory Integration

- Factory Integration

- Standard Packages

- 4 Step Quick Changeover

- QCO Management

Target Audience

- Development engineers, innovation engineers and product developers who wish to incorporate latest lean methodologies into their product development portfolio

- Manufacturing leaders who wish to reduce the factory integration issues and receive the perfect outcome from the development teams

- Entrepreneurs and business leaders who wish to imrove their innovation and product development capability

Transform Yourself Today!

Register for Next intake

- Investment : LKR 18,000

- 6 Consecutive Thursdays

- Conducted by Industry Experts

Program Schedule

Thursday 26th Aug, 2,9,16,23,30 Sep : 7.00pm to 9.00 pm (SL Time)

The Online Exam will be held on 2nd Oct Saturday (60 MCQs | 24 Hours).

Certificate of Participation

Learn from the Lean Experts

Asanka Henegedara

(Certified TPM Instructor MBA(PIM)|BSc Eng| ACMA| CGMA |Lean Six Sigma Black Belt)

- Director – ICEES Global

- Led multiple lean initiatives in Overall Lean Transformation and Special Tools including New Product Development, Quick Changeover and Total Productive Maintenance at MAS Group Lean Enterprise & Divisional Lean Enterprise for 9 years

- Has been mentored by Japanese Toyota consultants for 4 years

- Being Trained in Japan at Toyota Engineering Corporation (TEC), Nagoya; AOTS Chubu Kenshu Center, Nagoya; Exposure in Toyota Manufacturing, Warehousing and Distribution Facilities, Nagoya

- Conducted more than 100 workshops and trainings on Yellow Belt, Blue Belt, Green Belt, Advanced 5S, 8 Step Problems Solving and Value Stream Mapping, Total Productive Maintenance

- Experience in lean maturity assessments in 40+ textile and apparel plants in Sri Lanka, Bangladesh and Indonesia

- Possess MBA from Postgraduate Institute for Management (PIM), Bsc Engineering from University of Moratuwa and ACMA/CGMA from CIMA.

- Exposure to state-of-the-art manufacturing facilities such as Toyota Corporation in Japan and India

- Lean Six Sigma Black Belt and TPM Practitioner (JIPM)

Lapitha Gunasinghe

( TPS Instructor| MBA (ICFAI)| Industrial Eng (IMS)/Lean Black Belt/ Six Sigma Black Belt|)

- Director – ICEES Global

- Former Vice President – Lean Enterprise, inQube Global (Pvt) Ltd

- Former Country Manager, Quantum Apparel Cambodia

- Former General Director/ Head of Operations, Hop Lun Vietnam (Pvt) Ltd

- Former Deputy General Manager – Lean Enterprise, MAS Holdings (Pvt) Ltd

- former Manager – Lean Implementation, Walmart Global Sourcing (Pvt) Ltd, Bangladesh

- Former Snr Industrial Engineer, MAS Linea Aqua (Pvt) Ltd

- 20 years of working Experience in Manufacturing and driving Enterprise Excellence in Maldives, Bangladesh, Hong Kong, Vietnam, Cambodia and Sri Lanka.

- Have been mentored by Japanese & American Toyota consultants for 10 years. Being Trained in Japan at AOTS Chubu Kenshu Center, Nagoya and Toyota Engineering Corporation (TEC). Exposure in Toyota Manufacturing, Warehousing and Distribution Facilities, Nagoya

- Lean Black Belt – MAS Holdings

- Certified TPM Instructor – Japanese Institute of Plant Maintenance (JIPMs)

- Conducted workshops and training in MAS Lean Academy and Headed Blue Belt Training Program

- Successfully facilitated several continuous improvement projects and process innovation in different industries

Proudly Organized by

Innovation Center for Enterprise Excellence Solutions (ICEES) is a process innovation solutions provider specializes on Lean (Toyota Production System), Six Sigma and Total Productive Maintenance (TPM) concepts. Our vision is to enable potential by pioneering transformation for the good of individuals and enterprises. We deliver knowledge and solutions with our expert team that collectively possess 130+ years of hands on experience on enterprise transformation. To bring first hand lean knowledge, ICEES has partnered with Toyota Engineering Corporation in Japan.