Overcome Operational Gravity & Amplify Growth for Medium-Sized Businesses

We have been closely working with several medium-sized Sri Lankan businesses recently. All these businesses were owned and led by energetic young leaders who were fueled by a powerful vision for growth to become giants in their fields in Sri Lanka and the region. They have established their businesses remarkably well over the last decade with a profound customer base, reliable supply chain, dependable team, and more importantly a unique brand name. They are all set up to propel their businesses to the next level of growth. However, there is one problem that is bothering all of them.

The Problem

“It is very difficult to allocate good quality time to focus on my vision and business growth. I too much gravitate towards operational issues”.

“Now we are getting the orders. But I am struggling to keep the consistent quality and on-time delivery of my products”

“My team is the most trustworthy & experienced. But they still expect me to come down to some operational issues. I also doubt whether they can give the solutions, the way I do”

Above are some of the concerns they have put out to us. So, let us clarify the problem first.

All these businesses were started by these leaders or their families some years back and brought up to this level by giving a 200% personal commitment to every aspect of the business. In the start, their biggest worry was “How to get new orders?”. Whenever they received an order, they were able to give their personal time to deliver high-quality products on time. Over time, with the goodwill they developed with the customers, new orders and opportunities started to flow in even with a minimum effort.

Today, their problem has shifted from sales to operations. They are struggling to cope with the growing demand to supply the expected quality on time every time.

The problem is expected to get worsen when those one or two production modules with the most experienced and skillful operators getting expanded for ten, twenty, or even more, with a less experienced new set of people. Elon Mask faced a similar situation with the Model 3 Giga-factory expansion, where he mentioned the frustration as “Production Hell”.

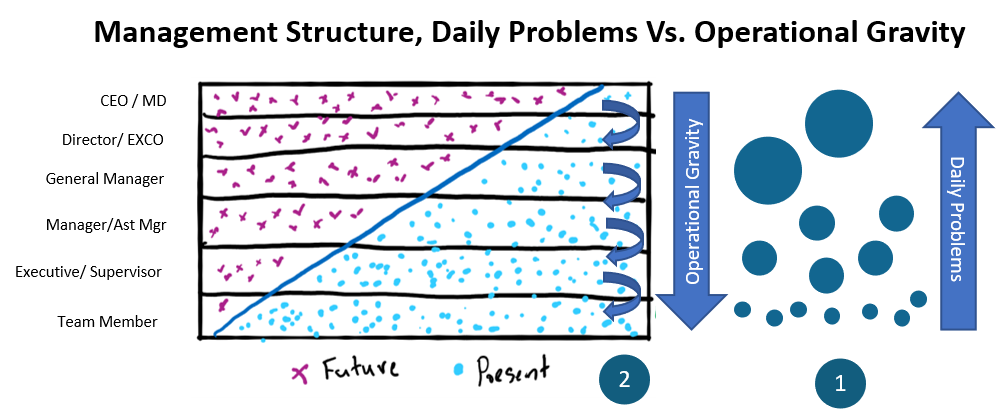

In a nutshell, the problem is, these leaders do not have sufficient time to focus on growth as they gravitate towards operational fire fighting. At ICEES we refer to this as “Operational Gravity”.

Higher the operational gravity in the business, the more time the leaders have to spend on operational matters and less time on strategic growth opportunities. Lesser the operational gravity in the business, the more time the leaders can spend on strategic growth matters and less time on operational fire fighting.

What is Operational Gravity ?

Operational Gravity is a multifactor phenomenon that is evident in many organizations. Factors such as lack of standard work, lack of operational measurements, lack of scientific problem solving, lack of people capability, lack of systematic review mechanism, and lack of visual management are some of the main causes that amplify the effects of operational gravity.

As depicted in above figure, when there are no or minimum standards, measurements or review mechanism established in the operational level, problems tend to accumulate and become strategic level issues over a period of time. Then the top level leadership will have to come down to sort these issues. When this becomes a habit, the operational level teams tend to frequently wait for the instructions from the top management. After some time, a vicious reactive cycle of firefighting, ask for instruction and leadership involvement for problem-solving will become a daily management habit. Such an organization needs to put in extra effort to break this reactive cycle and create a proactive, systematic, empowered culture with self-ownership.

How to Overcome Operational Gravity?

And that is the million-dollar question. How these medium-sized organizations can overcome the operational gravity. They need to build the rocket with a powerful throttle to outrun the operational gravity. for an organization, it is not as complicated as rocket science but needs a sound operational strategy to develop the below factors into their management system. Ok, let us ask these questions from you, and provide some high-level guidance on how to build those capabilities if you do not own them now.

1. Have you developed PROCESS STANDARDS for repetitive CTQ CTP processes

This is the most critical step. Setting up standards for all your repetitive processes. You can start with Critical to Quality (CTQ) and Critical to Process (CTP) processes. And remember this is NOT to qualify for ISO standards. This is to set up the base to the rocket to outrun the operational gravity. And make sure that all the standards are developed with key components; major steps, key points, timing, workplace standard, Min WIP, and Takt time.

2. Do you MEASURE the deviations?

It is very important that you have a system to measure data on all the process deviations. Start with a manual and later you can figure out high-tech digital measuring systems. More the numbers and figures you can measure, the stronger the problem highlighting mechanism will be.

3. How FAST can you get to know the deviations?

This is all about how strong your visual management system is. If your process deviations are visually highlighted as and when they are occurring, great! you have a real-time problem highlighting mechanism. In a strong visual environment, you should be able to identify a problem within 1 second it occurred. In a very strong visual environment, you can identify a problem before it occurs.

4. Are your people capable of SOLVING PROBLEMS SYSTEMATICALLY ?

It is not about ad-hoc plaster-type problem-solving. It is about solving problems systematically at the rate of production. The systematic way is arriving at countermeasures through proper root cause analysis, rather than jumping to conclusions with assumptions.

5. Is there a STRUCTURE that supports systematic problem-solving?

Your operational structure and hierarchy matter. Have you just employed some hands and legs to carry out operations on your production floor? Or do you have a structure similar to “Group Leader – Team Leader in Toyota” where even grass-root level team members are empowered to conduct systematic problems solving activities daily basis.

6. How do you REWARD people for systematic problem-solving?

This is not about once in a year awarding ceremony or family party. This is about leadership commitment to appreciate, challenge and mentor people at every level daily basis. Yes, we recommend you to adopt Lean Leadership behaviors where you will proactively allocate time in Gemba (Where value addition happens) to support your teams to learn. Developing your next-level team is the only way to free up time for you for strategic matters.

The above six factors are the most critical ones out of many factors. We can assure you that if you patiently activate the above guidelines in your organization, you will be able to free up considerable time for your future growth strategizing work.

See more >>